research

research

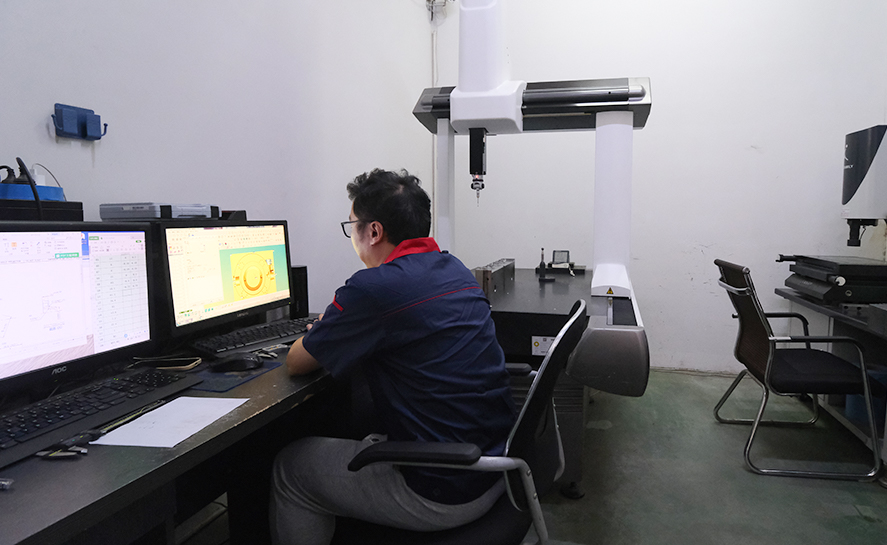

Design and development

- Double color Mould

- Thread screw parts

- Industrial Electrical Parts

- Other Customized Plastic parts

We focus on the design and manufacturing of precision plastic injection molds. We mainly design and produce precision plastic component molds for automobiles, electrical accessory molds, and dual color molds. We have a professional design team and a complete set of advanced precision mold processing equipment and high-precision testing equipment.

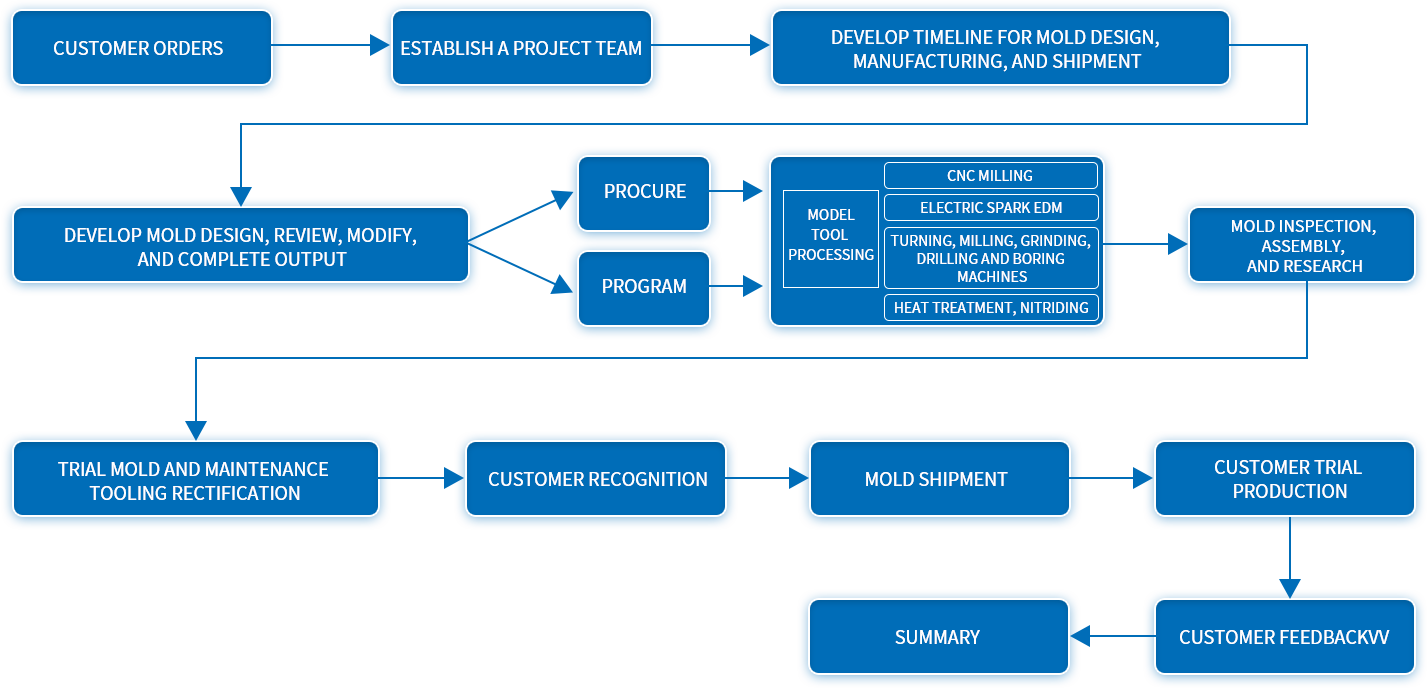

Mold manufacturing process

Mold inspection items

Raw Material Test

Raw Material Test

Mold material inspection

Material certificate

Mold material inspection report

Hardness, size, and other testing reports

Standard parts inspection

Hardness, inch and other testing reports

Use specification sheet and instructions

Mold inspection

Standard mold base inspection report

Electrode detection

Electrode detection report

Process Inspection

Process Inspection

Machining process inspection (machining center, electric spark, etc.)

Process inspection report

Heat treatment testing

Modulation, stress relief, nitriding, quenching, carbonitriding

Assembly process inspection

Mold accuracy testing report

Trial mold inspection

Trial mold inspection report

Demoulding inspection

Demoulding inspection report

Product Test

Product Test

Full size inspection

Three coordinate detection center

Testing of trial samples

Delivery Inspecion

Delivery Inspecion

Mold inspection (appearance, spare parts, instructions, etc.)

Mold shipment inspection form

Packaging inspection (material, size, fit, etc. of packaging)

Packaging Review Report

project management